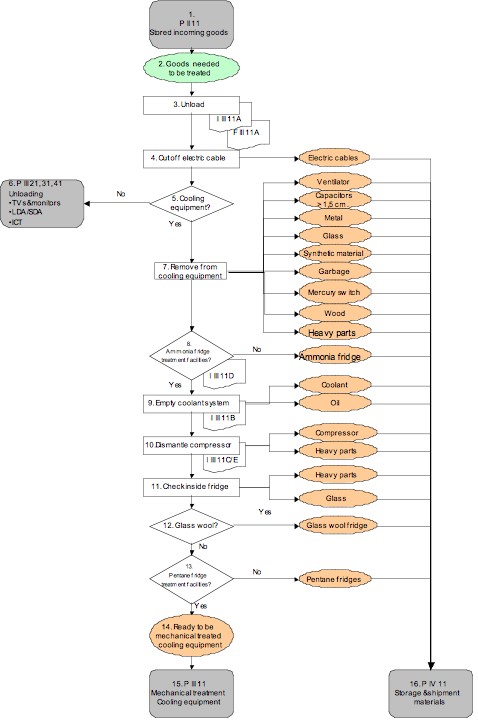

Process Details

- The cooling equipment has been accepted.

- The cooling equipment is in storage waiting to be processed.

- The production employee unload the cooling equipment, according to instruction I III 11A and fills out F III 11A.

- First the production employee cuts off the cable.

- If it is not cooling equipment the production employee informs the shift leader. He decides to continue or to refuse the load. See P II 11.

- When continuing the non-cooling equipment will be stored and processed elsewhere.

- The production employee manually takes off hazardous material and waste.

- The production employee sorts out the ammonia fridges. The ammonia fridges will stored to be processed elsewhere. The production employee drains the compressor of the cooling equipment according to I III 11B.

- The production employee cuts the compressor of the cooling equipment according to I III 11C/E.

- The production employee checks inside the fridge for glass or heavy parts according to I III 11C/E.

- The production employee sorts out the glass wool fridges. The glass wool fridges will be stored to be processed elsewhere.

- When the plant has no possibility to process pentane fridges, he sorts out the pentane fridges. The pentane fridges will stored to be processed elsewhere.

- The result is a cooling appliance ready for further mechanical treatment.

- P III 21 describes how the cooling equipment is mechanically treated.

- How to store and ship all the sorted out materials is described in P IV 11.